FERROSCANNING

KEY FEATURES OF FERROSCANNING

Ferroscanning can provide information on the building structure without the need for intrusive surveys.

It can detect bar diameters, spacing and concrete cover and is effective up to a depth of 140mm.

It can assist with the precise core drilling in concrete structures, minimising the cutting of rebar.

It can assist with the precise core drilling in concrete structures, minimising the cutting of rebar.

WHAT IS FERROSCANNING?

The machine we use is the Hilti PS200 Ferroscanner which can provide information on your RC structure without the need for intrusive surveys to expose rebar patterns, and the subsequent making good that goes with it.

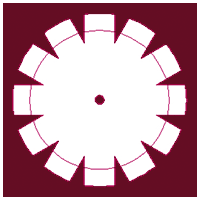

A Ferroscan survey detects the presence and position of rebar within a reinforced concrete element. It can also tell bar diameters, spacing and concrete cover and is effective up to a depth of 140mm. It can detect other cast-in metal objects, but cannot detect non-metallic objects.

We can offer a survey with a full written report including imaging (this has to be completed off-site), or we can offer a quick scan on-site, if you only wish to mark bar positions on a slab or wall, for example.

ACCREDITATIONS

HOW DOES FERROSCANNING WORK?

A Ferroscan survey detects the presence and position of rebar within a reinforced concrete element. It can also tell bar diameters, spacing and concrete cover and is effective up to a depth of 140mm. It can detect other cast-in metal objects, but cannot detect non-metallic objects.

| Point: | x: [mm] | y: [mm] | Cov.: [mm] | Bar: | Orientation: | Usage: |

| 1 | 96 | 60 | 40 | 12mm | Horizontal | Measurement |

| 2 | 246 | 67 | 40 | 14mm | Horizontal | Measurement |

| 3 | 546 | 58 | 42 | 25mm | Horizontal | Measurement |

| 4 | 589 | 57 | 44 | 28mm | Horizontal | Verify only |

| 5 | 117 | 163 | 42 | 6mm | Horizontal | Measurement |

| 6 | 267 | 165 | 42 | 8mm | Horizontal | Measurement |

| 7 | 396 | 167 | 40 | 6mm | Horizontal | Measurement |

| 8 | 567 | 165 | 47 | 12mm | Horizontal | Measurement |

| 9 | 117 | 251 | 43 | 6mm | Horizontal | Measurement |

| 10 | 353 | 251 | 43 | 8mm | Horizontal | Measurement |

| 11 | 589 | 258 | 42 | 16mm | Horizontal | Verify only |

| 12 | 524 | 396 | 42 | 6mm | Horizontal | Measurement |